Precision Nozzle Band Heaters

Optimal Heat for Injection and Extrusion Nozzles

Drive consistent process performance with Caldor’s Nozzle Band Heaters — engineered for reliable, uniform heat delivery in tight spaces and demanding industrial environments. Designed for injection molding, extrusion, and high-temperature applications, our heaters help ensure stable nozzle temperature and improved product quality.

Request a quote!

Nozzle Band Heater Manufacturing

Temperature Performance & Applications

Caldor Heat Engineering’s Nozzle Band Heaters are specialized industrial heating elements designed for consistent thermal control of nozzles and similar cylindrical components in injection molding and extrusion machines. Manufactured with precision and industrial-grade materials, these heaters provide reliable heat transfer and stable temperature maintenance in challenging production environments.

These heaters are engineered for use where space is limited and precise heating is essential. They feature a heat-resistant construction with a robust outer sheath and quality insulating materials to ensure durability and performance under continuous operation. Caldor’s Nozzle Band Heaters are hermetically sealed to prevent liquid material infiltration, safeguarding performance and extending service life.

Typical operating temperatures support standard industrial plastic processing needs, with peak performance that maintains uniform nozzle temperature and minimizes thermal fluctuations — crucial for producing high-quality parts and efficient cycle times.

Key Features

- Tailored Thermal Performance: Designed to deliver focused and uniform heat precisely where required on the nozzle surface.

- Space-Efficient Design: Compact construction ideal for installations with limited clearance.

- Sealed Construction: Hermetically sealed against liquid polymer ingress, enhancing reliability and lifespan.

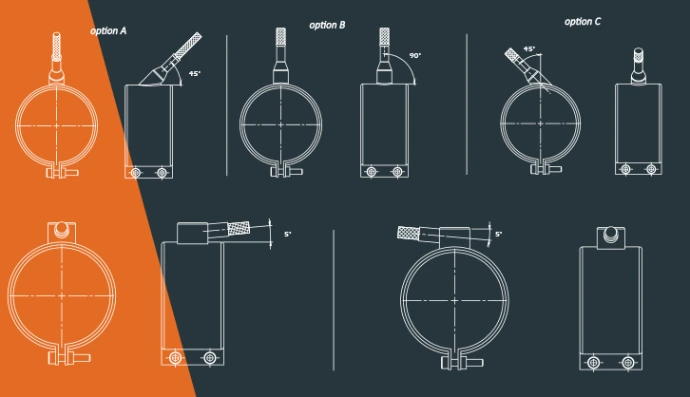

- Flexible Cable Exit: Options for single cable exit and customized cable positioning to suit your installation requirements.

- Optional Thermocouple Integration: External thermocouple installation available to support precise temperature control systems.

- Durable Materials: Constructed with quality metal sheaths and insulation for long service life and robust performance.

Industrial Applications

Caldor’s Nozzle Band Heaters are engineered for a wide range of industrial thermal applications, especially where precise temperature control directly influences product quality and process efficiency:

- Injection Molding Machinery: Maintain consistent nozzle temperature to ensure uniform melt flow and defect-free parts.

- Extrusion Systems: Targeted heating at nozzle points to sustain material flow and processing stability.

- Hot Runner Systems: Support critical thermal management in tools and assemblies where temperature uniformity is essential.

- Specialized Equipment: Heating for pistons, melt delivery assemblies, and machines requiring compact, reliable heat sources.

Why Choose Caldor’s Nozzle Band Heaters

Industrial Quality Engineering:

Each heater is manufactured to meet demanding industrial standards with rigorous quality control to ensure durability and performance.

Reliable Temperature Maintenance:

Our designs promote stable, consistent heat transfer — critical for repeatable production processes.

Customizable Solutions:

Caldor can adapt heater dimensions, power ratings, and cable configurations to your specific application requirements.

Hermetic Protection:

Sealed heater construction prevents material infiltration, increasing reliability and reducing downtime.

Trusted Industrial Partner:

With extensive experience in industrial heating solutions, Caldor delivers technical expertise, responsible support, and high performance across applications.

A nozzle band heater is a specialized industrial heating element designed to provide accurate and concentrated heat to nozzles and small cylindrical components used in injection molding and extrusion systems. Its primary role is to maintain a stable and uniform temperature at the nozzle, ensuring consistent material flow and high-quality end products.

Nozzle band heaters are manufactured using high-grade insulating materials and durable metal housings, allowing them to operate reliably in high-temperature and high-pressure industrial environments. Their compact design makes them ideal for applications where installation space is limited, while still delivering efficient heat transfer directly to the heated surface.

These heaters are commonly used in plastic injection molding machines, extrusion lines, hot runner systems, and packaging equipment, where precise temperature control at the nozzle is critical. By minimizing heat loss and thermal fluctuations, nozzle band heaters help prevent material degradation, reduce cycle times, and improve overall process efficiency.

A key advantage of nozzle band heaters is their fast thermal response, enabling quick start-up and rapid adjustment to temperature changes during operation. They are also available in custom dimensions, power ratings, and cable configurations, allowing seamless integration into both standard and specialized industrial systems. With their robust construction, long service life, and low maintenance requirements, nozzle band heaters represent a reliable and cost-effective solution for demanding industrial heating applications.Technical & Commercial Inquiries for Custom-Engineered Band Heaters

Contact our engineering team to request detailed quotations and submit technical specifications for customer-focused, application-specific band heater solutions.